Special features

| Robust design | For professional use. (Patent protected) |

| Excellent cutting performance | High harvesting speed, high tonnage results per hour |

| Improved cutting | Clean base cut and no stool damage |

| Long service life | Patented ESM Carbodux® knife sections resistant against foreign obstacles like stones etc. |

| Safety breakaway mechanism | Automatic spring release system |

| Minimal maintenance | Low blade speed; minimal blade wear; easy replacement of knife assemblies |

| Environmentally friendly | Low power consumption |

| Easy handling | Three point linkage system fortractor rear lift linkages Cat I/ll, hydraulic cutter bar lifting system, weight transfer floating system for inner shoe driving mechanism, cuts lodged cane, cuts green cane |

Technical data

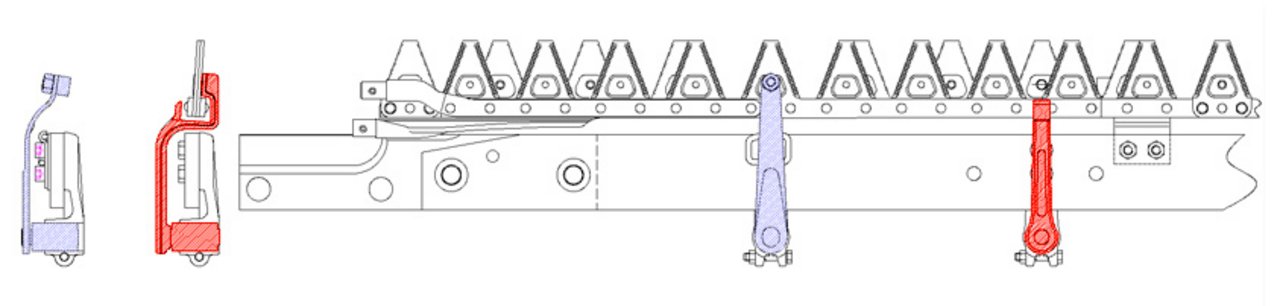

| Double knife Cutting Unit | ESM |

| Cutting width | Depending on row spacing with a choice of 1.1 and 1.7m cutterbar lengths |

| Section Pattern | 80 - 96 mm |

| Section Execution | ESM CARBODUX® hardfaced |

| Cutting Speed | Depending on conditions from 0.8km/h - 4km/h |

| Power consumption per 1m of per 1m of cutting | max. 3kw |

| Knife driving system | Heavy duty open pivot cutter drive, easy and simple to maintain, PTO shaft driving a hydraulic pump that powers the cutter drive |

| Carrier | Any tractor with 540 rpm PTO and CAT1/2 rear lift linkage |

| Cutterbar Safety breakaway mechanism | Automatic spring release system |

| Transport System | Cable retaining cutterbar in vertical position |

| Cutterbar lifting system | Manual or hydraulic depending on tractor Specs |